Black Oxide is a pretty common finish for hardware, and I personally prefer the look of black oxide over stainless or zinc coatings. That said, I have had terrible luck with black oxide hardware rusting in a very short amount of time on my cars. I would avoid using this finish on your Subaru (or any car).

My MSI steering rack bushings came with black oxide hardware. While these aren’t completely exposed to the elements due to the undertray, one bolt started rusting almost immediately. By the time I replaced them, one bolt was covered in rust, and the other one was showing signs of rusting.

I ordered a replacement set of zinc plated steel bolts from McMaster-Carr. Normally, I buy my hardware from Bolt Depot; however, they didn’t have the size I wanted in JIS spec. So far, no rust. If you are interested in a set for yourself, the specs are:

- M10 x 1.25mm x 60mm (JIS) [https://www.mcmaster.com/95735A661/]

- M10 x 1.25mm x 50mm (JIS) [https://www.mcmaster.com/95735A651/]

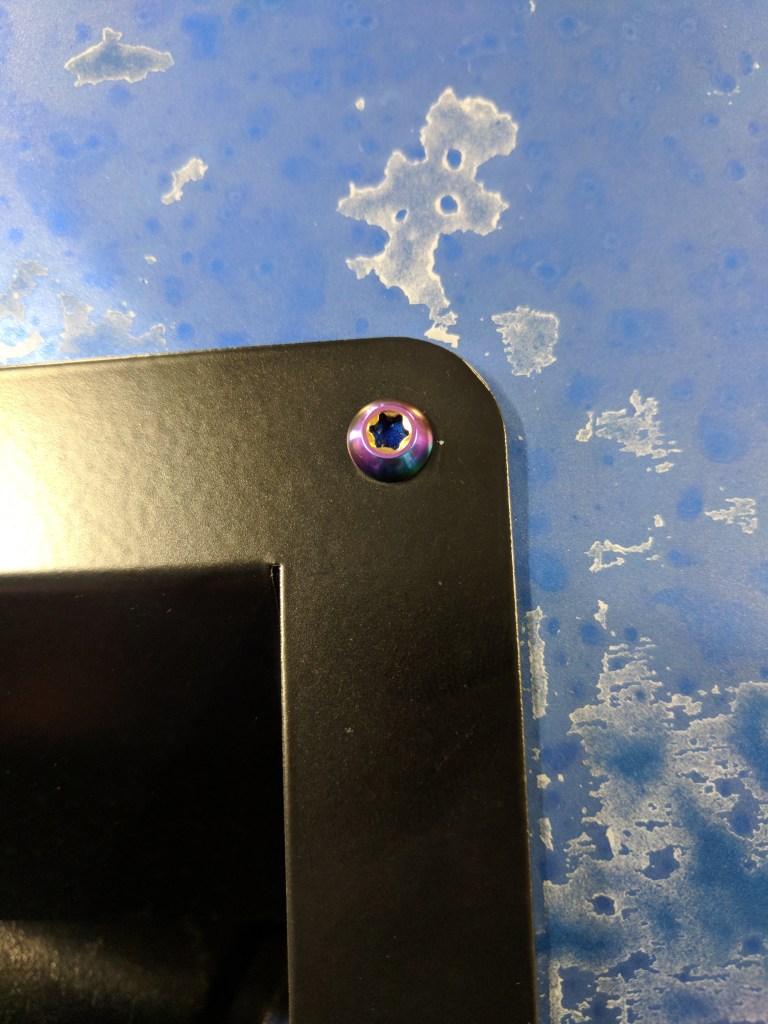

Before the steering rack bolts, I also tried a set of black oxide bolts on my hood vents. They rusted within a week, so I eventually replaced them with titanium bolts from eBay. I initially ran stainless bolts, but they reflected a laser beam of sunlight right into my eyes.

After some light research, it appears that black oxide is little more than stable rust. It does provide some mild corrosion protection. However, exposure to water will cause the hardware (unless it is stainless black oxide) to rust pretty quickly. Rusty hardware is one of the worst things to deal with on a Subaru.

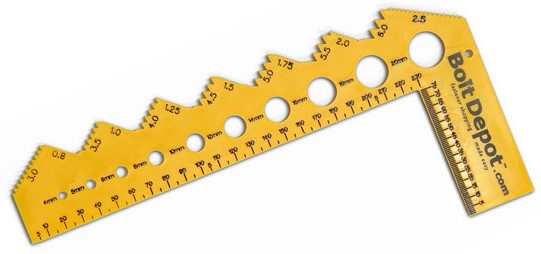

If your new car part comes with black oxide hardware and that component will be exposed to the elements, basically anything suspension or chassis-related, I strongly recommend replacing it with stainless or zinc-coated hardware. If you don’t have one, I highly recommend this L-gauge from Bolt Depot. I use it all the time to measure my hardware. It will make your life a lot easier to find replacement hardware.

Cheers!

Leave a comment